Hi All

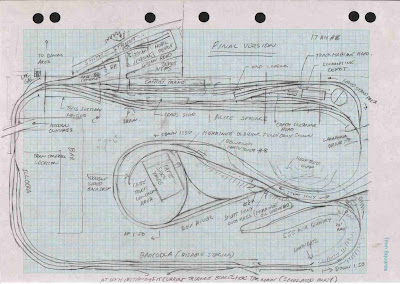

For all of my friends that have had to put up with me sticking enless layout diagrams under their nose for coment please see the two images are plans of a future Alice Springs layout which will include Barcoola in name only, Barcoola is basicly an open staging yard. The First version has no duck unders and long distances between locations and the section around the edge of the room are double stacked, the lower level is Barcoola - northgate(southern open staging) and the upper level is Berrimah yard (northern opern staging). This version was finaly rejected due to a couple of factors.

1 the radi at Bow River was just too tight.

2 too much hidden trackage, the southern line would have to be unseen from the south switch of Bow River to just out of Barcoola.

3 Too many grades, although they were not steep, they would just be a complete pain to construct, thus it would take longer to construct.

4. Alice Springs yard would be too squashed and curvy, all thoes curved points would create problems shunting.

5 not enough people space, and the plan was not linear, meaning when you are at one part of the layout you would then have to walk around the entire layout just to keep track, this would increase the aisle traffic dramiticly.

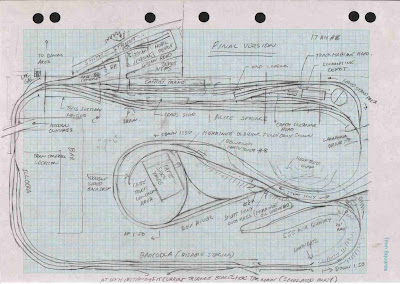

Late last night I came up with the final version, one I would call "proof of concept".

this version is not walk in, but is linear.

Alice Springs yard is easier to shunt, it is longer and more managable, I have positioned all the points out on the floor and checked the track lengths using Micro Engineering #6 points.

Alice Springs industrial area is better represented as a "mini layout" and the roads are the correct orientation.

All sidings are 22ft clear standing distance.

Plenty of space for operators and "train control" (the Bar)

I have added the 555km Quarry as this will keep train control busy with addtional train orders from Barcoola to 555km.

Anyway I hope this makes some sence.

thanks

Scott